Testas

warehouse

Testas is a wholesaler of non-ferrous metals, which is part of the group MCB (Metaalcompagnie Brabant). That is anything but pure steel, just think of aluminum, stainless steel and copper. For this we provide storage in the form of plates and profiles.

Who is Testas

Can you briefly tell us what your company’s core business is and what you consider to be the biggest challenges?

Testas is a wholesaler of non-ferrous metals, which is part of the group MCB (Metaalcompagnie Brabant). That is anything but pure steel, just think of aluminum, stainless steel and copper. For this we provide storage in the form of plates and profiles. We will then package them in a customer-specific manner (for example, a specific alloy or size). We are also responsible for the rough sawing, so that the customer can continue with the product in a further phase. Extra added value to the products is therefore not part of our core business. Testas focuses mainly on the Belgian market, but you will also find us in Northern France, Luxembourg and a small part of the Netherlands.

Initial need

What was the initial need within your organization to build a storage shed together with Frisomat?

With our first expansion after the acquisition in 2008, we realized that additional space was crucial to further grow the business. That is why we decided to have an extra warehouse built in 2016, so that we do not run out of space. In 2018, we again opted for the services of Frisomat for a new storage warehouse, which was completed earlier this year (2019).

Requirements

What matters were of crucial importance to you in realizing this storage warehouse in order to be able to work optimally now and in the future?

It was especially important to us that, after delivery, we still had a lot of freedom ourselves . We use racks to store material, which makes the use of intermediate columns extremely inconvenient. With a steel construction that fully supports the roof, without extra support from intermediate columns, we have all the freedom to

arrange the hall in the way that suits us best . For example, if our situation changes, we still have the option to make changes.

Expertise

We entered into a partnership to build your bulk storage warehouse and the aim was to achieve an optimal result together, but how did you end up at Frisomat and why did you ultimately choose our expertise?

The headquarters of Testas is located in the Netherlands, with steel as its core business . This is how our preference for (a) steel construction(s) arose. The choice was therefore quickly made when we started looking for extra storage space in 2016. Frisomat itself has been known to us for some time , because they are our neighbour. Like us, they opted for the peaceful surroundings of Wommelgem/Wijnegem. Moreover, there was already an existing relationship between the owner of Frisomat and the management team of Testas. Naturally, Belgian-made and us-know-us also play an important role: why dive into the unknown, when you can go into the sea with your neighbour! We therefore sat down with Frisomat, and that quickly led to results: our new storage sheds. The information flow was short, and both the transport and the follow-up went very smoothly.

Want to build your own storage shed?

Process

How did you experience the process of building the storage shed?

The construction of our first Frisomat storage shed in 2016 went off without a hitch. Both the services during the process and the result were there .

The initial start of the second pilot was a little less smooth. Due to a number of internal shifts, we experienced problems, which resulted in a longer than usual process. However, Frisomat immediately took action and made the necessary adjustments internally. Partly due to the appointment of another project leader, the project continued to be professionally worked on, which ultimately led to a qualitative result . Both in terms of the management of the process and the quality of the warehouse.

As soon as the concrete ring beam was poured, everything went smoothly.

We are also very satisfied with the communication . Almost every morning the project manager visited the site and we discussed the progress. In the event of a problem, communication was immediate and a solution was sought. The follow-up was therefore extremely professional .

Nowadays

How do you use the bulk storage warehouse in your organization today and does that meet your initial objective?

Testas mainly had a problem with space. With so many different sizes and alloys, depending on the customer, logistics falters when there is a shortage of storage space. With a Frisomat steel warehouse we were able to create extra space , absolutely necessary for our sector, because ‘if you don’t have it lying around, you won’t sell it’. Our warehouses are therefore used as a

bulk storage hall for flat plates, in order to expand storage capacities.

New challenges

Are there new challenges for which you would call on Frisomat again?

We are currently discussing a growth plan for possible expansion, but for the time being this is only reflected in a market study into the potential. However, extra space will certainly be needed, for which we would like to work with Frisomat again .

Due to the targeted action that Frisomat took, and the professional follow-up of the project leader, Frisomat delivered an excellent result.

Advice

What advice would you give to future organisations that want to build a warehouse?

Before you proceed to actually build a steel shed, it is best to have a soil probe carried out . This way you know exactly what the quality of your surface is. This way you avoid a lot of ambiguity, and the process moves forward much faster. Both the calculation of the foundation and the pouring of the concrete slab can run much more smoothly this way. In addition, steel construction is a good choice for a storage hall. This way you have a finished storage hall in record time, which you can use immediately.

Building solution: Warehouse

Customer: Testas

Location: Belgium

Regional Manager Africa

Thomas Waterkeyn

Let’s discuss your project

Frisomat offers the perfect solution for your steel hall needs. Our unique building system allows for quick and efficient assembly, bringing your dreams to life in no time.

Our process behind your new building

Design

Frisomat has everything companies and entrepreneurs need to realise their dreams. Our more than 35-strong engineering and design team will create your dream in steel.

Read morePRODUCtION

With our 30,000m² state-of-the-art automated facilities, we efficiently produce all the building blocks for your steel dream. Thanks to years of experience and expertise, we know exactly how to create your dream structure.

Read moreDELIVERy

We deliver your steel dream in the shape of cold-formed steel, which is 30% lighter and 50% less voluminous. This efficient method ensures cost-effective transport and fast delivery of your steel building.

Read moreASSEMBLY

Build your dream building with the help of our African partners or under the guidance of a Frisomat supervisor. Our aim is to guarantee a construction process that is both fast and efficient.

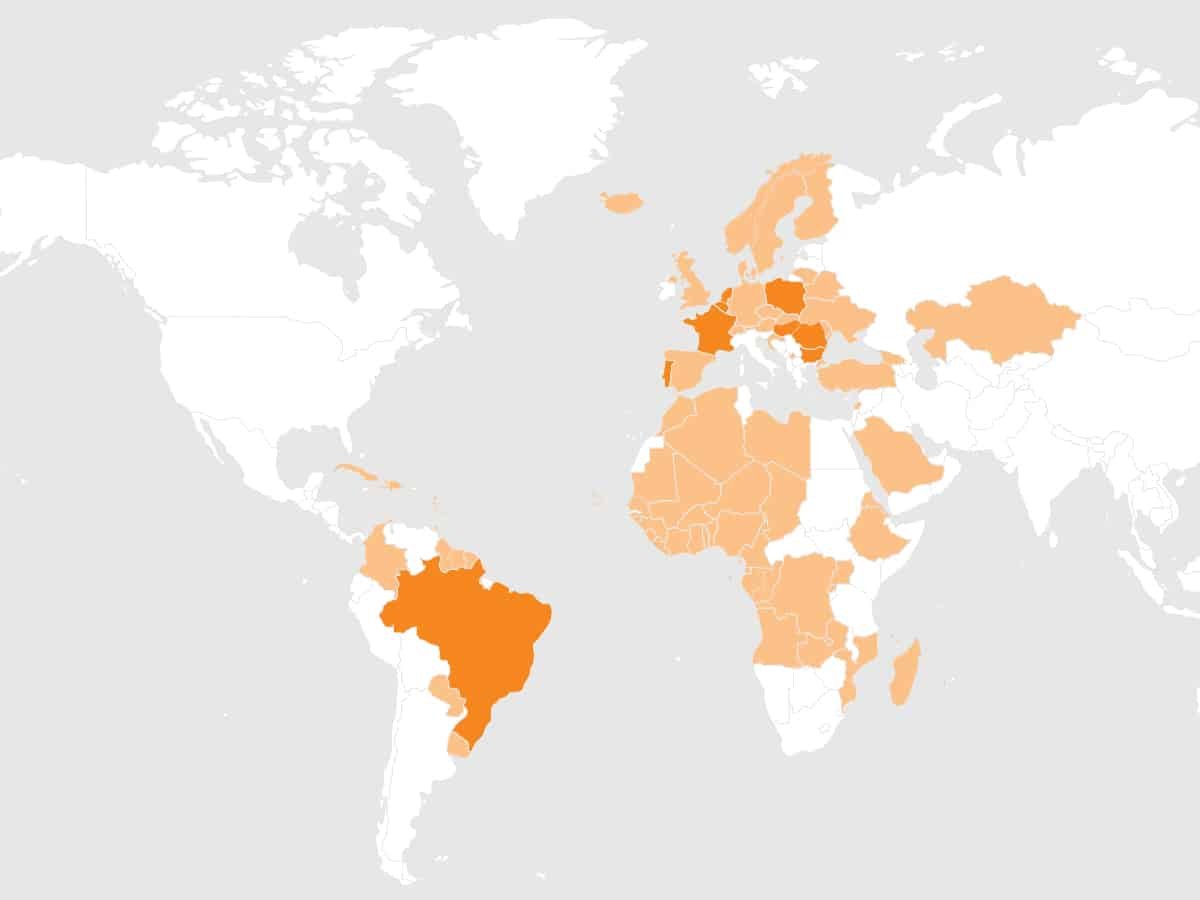

Read moreGrow internationally with a global player

350 Employees

37,000 buildings worldwide

+10,000 tonnes of steel / year

1985, first building delivered in Africa

+1,600 projects in +40 African countries

+60 African partners for foundation and assembly

Chat with an expert

Want to discuss your needs with an expert? Fill out the form below and chat with one of our professionals, no strings attached.

Message