Henri Fraise & Fils

industrial BUILDINGS

Henri Fraise & Fils, a Frisomat partner, provides equipment to one of the largest nickel mines in the world, Ambatovy. This mine, located in Madagascar, required an elevated steel building in order to protect their processing equipment and machinery from strong weather conditions.

Special steel building specifications

Frisomat’s well-experienced engineers had to take into consideration both local conditions as well as unique customer requests. Madagascar is an island of the coast of East Africa that can have considerably high winds and cyclones during the rainy season. Frisomat was entrusted to build a sturdy and robust structure which was reinforced to withstand those high winds.

Though the steel building was both standard and small in size (13 metres long by 4.5 metres high), it had to be installed on top of a steel frame and beams measuring 2 and a half meters high. This is uncommon, as most buildings have a concrete foundation underneath. Frisomat was able to satisfy this specification by providing a lightweight hinged foundation to sit on top of the steel frame and beams. Frisomat supplied a building with a steeper roof inclination, giving the customer more space in the centre of the elevated building.

Frisomat builds customer trust and loyalty

Frisomat has a strong long-standing relationship with Henri Fraise & Fils, having supplied more than 10 steel buildings to the company over the years. They trust Frisomat to supply prefabricated buildings that are easy to assemble and long lasting. In this case, the building process was both swift and smooth and completed in under a week. The customer was completely satisfied with how the building turned out and they’ve asked Frisomat to help with another building project starting soon.

Building solution: Industrial buildings

Customer: Henri Fraise & Fils

Location: Madagascar

Regional Manager Africa

Thomas Waterkeyn

Let’s discuss your project

Frisomat offers the perfect solution for your steel hall needs. Our unique building system allows for quick and efficient assembly, bringing your dreams to life in no time.

Our process behind your new building

Design

Frisomat has everything companies and entrepreneurs need to realise their dreams. Our more than 35-strong engineering and design team will create your dream in steel.

Read morePRODUCtION

With our 30,000m² state-of-the-art automated facilities, we efficiently produce all the building blocks for your steel dream. Thanks to years of experience and expertise, we know exactly how to create your dream structure.

Read moreDELIVERy

We deliver your steel dream in the shape of cold-formed steel, which is 30% lighter and 50% less voluminous. This efficient method ensures cost-effective transport and fast delivery of your steel building.

Read moreASSEMBLY

Build your dream building with the help of our African partners or under the guidance of a Frisomat supervisor. Our aim is to guarantee a construction process that is both fast and efficient.

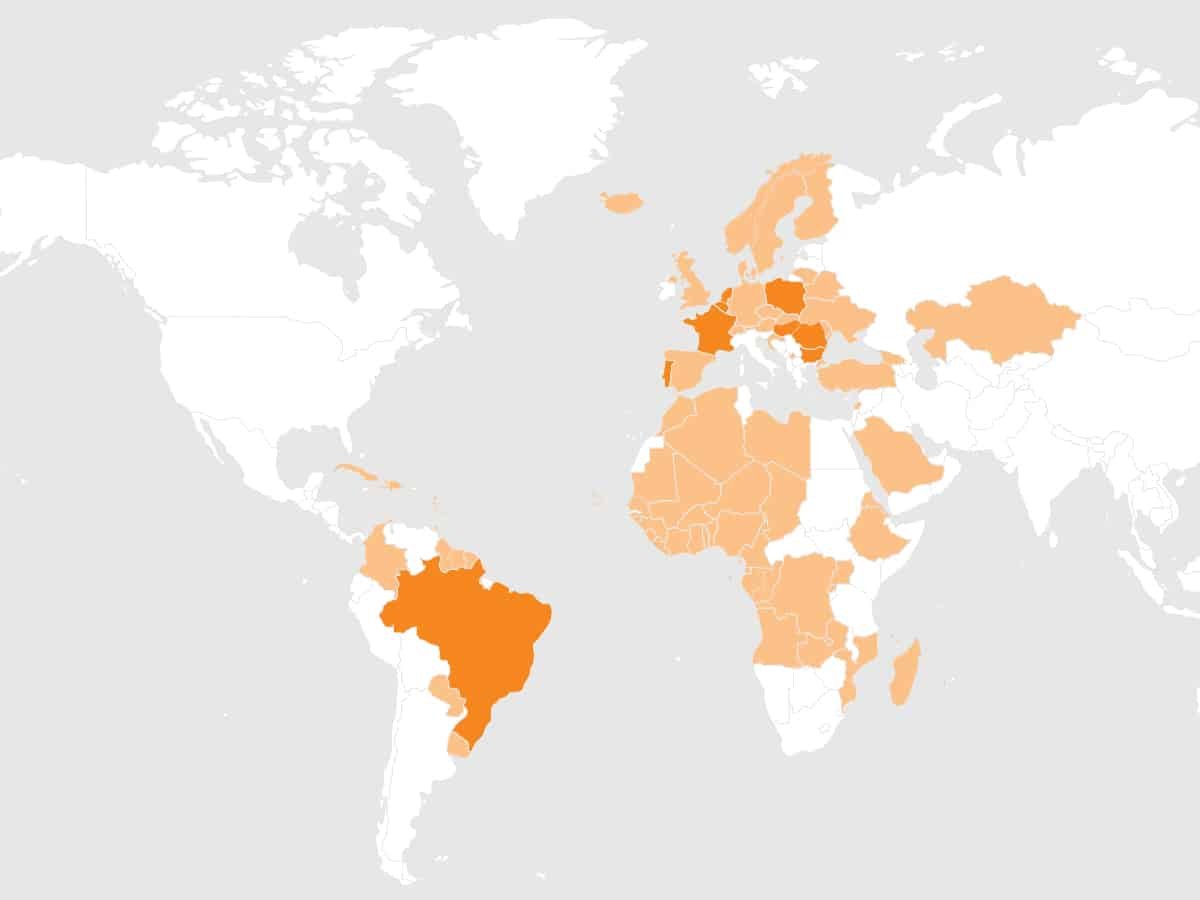

Read moreGrow internationally with a global player

350 Employees

37,000 buildings worldwide

+10,000 tonnes of steel / year

1985, first building delivered in Africa

+1,600 projects in +40 African countries

+60 African partners for foundation and assembly

Chat with an expert

Want to discuss your needs with an expert? Fill out the form below and chat with one of our professionals, no strings attached.

Message