Africa Motors

CAR SHOWROOM AND WORKSHOP

In Pointe Noire (Congo-Brazzaville), the oil centre of the Republic of Congo and the largest deep sea port in the region, a local assembly team is assembling a car showroom/workshop for luxury cars. “The total surface area is almost 1,500 m²,” says the site manager. “We’ve been going for nearly three months, and the luxurious hall is almost finished now.” Discover in this video the comfort of working with cold rolled galvanised steel. And find out how this type of steel stands up to the salty climate.

Local team assembles 1,500 m² hall in 3 months’ time

In Pointe Noire, between the Avenue de l’aéroport and the Mutech Réseau, less than 1000m from the international airport, a car showroom/workshop for luxury cars is not an unnecessary luxury. Entrepreneurs like to drive around in style with such cars. Obviously, the showroom was to be operational as quickly as possible. Time is money in an economic metropolis like Pointe Noire. A local team assembled the entire workshop in less than 3 months. “All profiles were assembled in two days,” says the site manager. The showroom was up and running in no time.

Car showroom/workshop in Pointe Noire, the economic capital of Congo-Brazzaville

Serve the Congolese market. This is the purpose of the car showroom/workshop for luxury cars currently being assembled in Pointe Noire, the oil centre of the Republic of Congo. A local site manager and his team ensure the smooth progress of the project: “We like working with Frisomat. We have not had any problems with them.” And it is a collaboration that pays off. The 1,500 m² luxurious hall was completely finished in just three months.

Building solution: Showroom and workshop

Customer: Africa Motors

Location: Pointe Noire, Republic of Congo

Area: 1.500 m²

Export Manager

Johan Van Den Hemel

Let’s discuss your project

Frisomat offers the perfect solution for your steel hall needs. Our unique building system allows for quick and efficient assembly, bringing your dreams to life in no time.

Our process behind your new building

Design

Frisomat has everything companies and entrepreneurs need to realise their dreams. Our more than 35-strong engineering and design team will create your dream in steel.

Read morePRODUCtION

With our 30,000m² state-of-the-art automated facilities, we efficiently produce all the building blocks for your steel dream. Thanks to years of experience and expertise, we know exactly how to create your dream structure.

Read moreDELIVERy

We deliver your steel dream in the shape of cold-formed steel, which is 30% lighter and 50% less voluminous. This efficient method ensures cost-effective transport and fast delivery of your steel building.

Read moreASSEMBLY

Build your dream yourself with our assistance, or leave the assembly to us. If we have an affiliate near you, we’ll assemble your entire steel hall for you. When we bring your vision to life, we focus on efficient and swift construction.

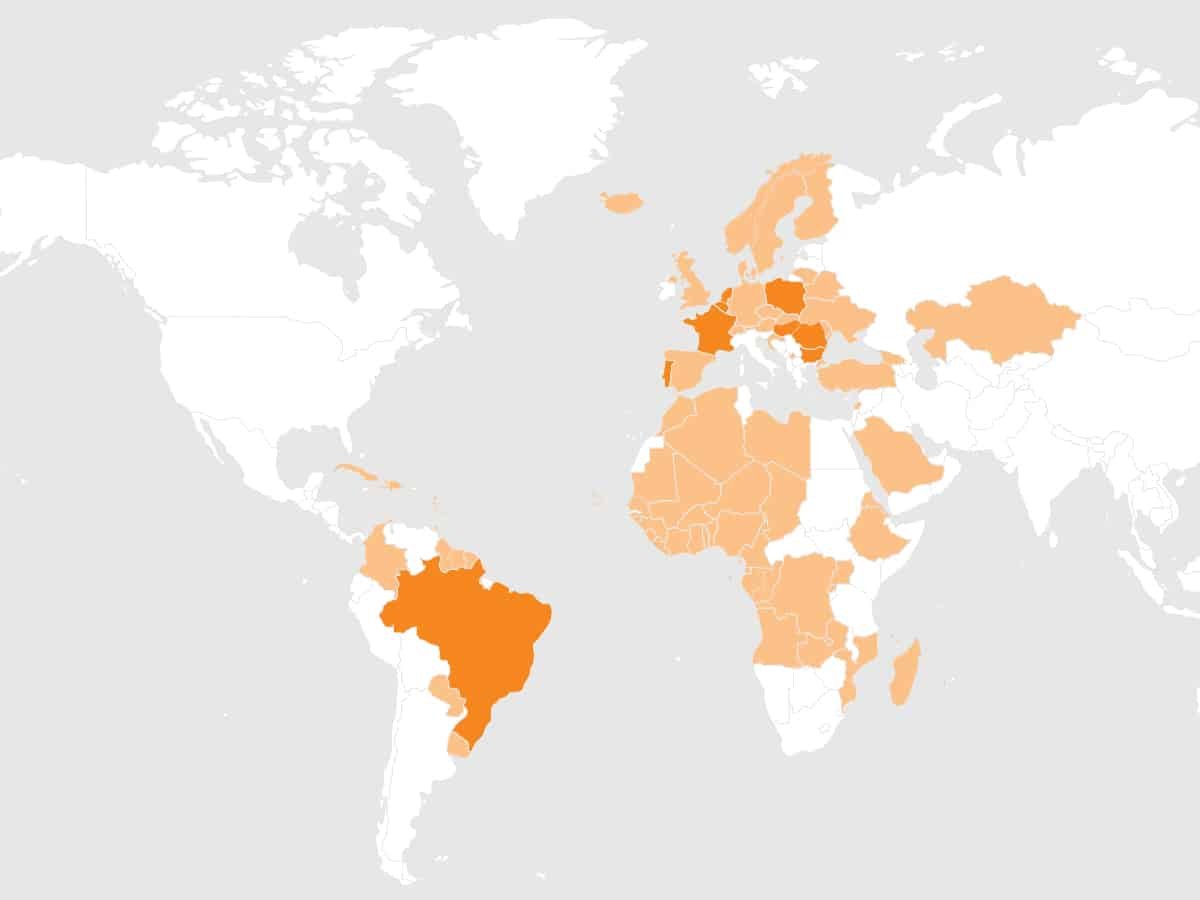

Read moreGrow internationally with a global player

37,000 buildings

350 Employees

100+ Countries

+10,000 tonnes of steel / year

Chat with an expert

Want to discuss your needs with an expert? Fill out the form below and chat with one of our professionals, no strings attached.