Cold-formed (CFS), galvanised steel

WHY CHOOSE COLD-FORMED, GALVANISED STEEL?

At Frisomat, we manufacture buildings from cold-formed (CFS), galvanised steel. Although the base material is the same as hot-rolled steel, the process of cold forming during post-treatment improves the strength properties. Essential for the durability of our steel buildings.

Want to discuss your project?

The production process of our cold-formed steel

GALVANISED STEEL

Frisomat uses pre-galvanised steel bought in coils. Galvanisation is carried out in a strictly controlled environment to ensure accurate layer thickness, which avoids unnecessary zinc consumption.

EQUALISING THE STEEL

We flatten the steel by removing stresses from unrolled coils. This guarantees optimal profiling later.

Punching of holes

Our technical department programs stamping templates in our computer-controlled machines. The necessary holes, which are essential for smooth assembly, are punched accurately. Thanks to minimal tolerances, we can guarantee perfectly fitting parts.

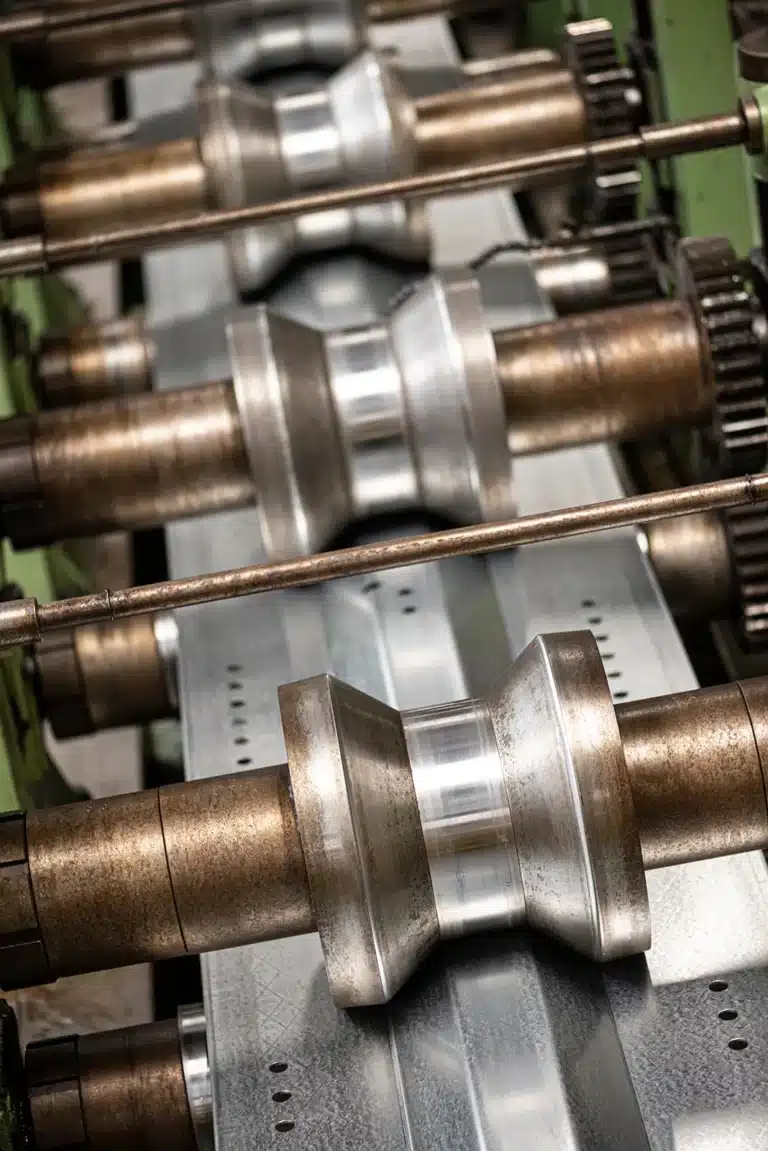

profiling of steel

Steel is gradually deformed, starting from the centre of the coil towards the edges, to create the desired profiles. Using multiple profiling lines, we transform flat, thin sheets (up to 5 mm thick) into columns, beams or other elements of our buildings.

CUTTING OF PROFILES

The steel profiles for the columns and beams are cut to length during the production process, contributing to a continuous production flow and minimal production waste.

Looking to buy a steel building or structure?

Request a quote

Advantages of cold-formed, galvanised steel

Galvanised steel on coils only needs to be stamped and profiled (cold formed) into columns, beams and other elements. Additional post-treatments such as painting or galvanisation, which are required with hot-rolled steel, are no longer necessary. This increases efficiency.

Moreover, our precast elements are more efficient in transport and assembly, due to their light weight and simple bolted connections. Allowing a small team to quickly construct an industrial building with light materials, significantly reducing construction time.

CORROSION RESISTANT

Each component is zinc-coated for long-term protection against corrosion. This ensures that your building remains in excellent condition for many decades.

STRUCTURAL STABILITY

Our steel structures are exceptionally sturdy despite their thin profile thickness of just a few millimetres. This is due to the use of high-quality steel combined with our innovative profiling. This makes it possible to build larger and taller buildings than with traditional methods.

Read more in the comparison of steel and concrete construction

LIGHT AND STRONG

Cold-formed steel is lighter than other traditional building materials, resulting in lower loads on foundations, more efficient transport and faster assembly. This makes it ideal for industrial construction projects and exports, and also results in cost savings.

Read more about the cost price of a steel building

Quick assembly

Our lightweight, prefabricated building elements feature pre-punched holes and efficient bolted joints for fast assembly. This allows a small team to realise industrial buildings quickly and effectively with lightweight materials, significantly speeding up the construction process.

Read more about the assembly of your Frisomat building

PRECISION

With an extensive range of thicknesses, varying in 0.5 mm increments, we always use the most suitable profile for each site, making efficient use of material and costs.

FLEXIBILITY

Cold-rolled steel allows us to quickly design various types of profiles. We also keep adding new options to our range.

ECO-FRIENDLY

Cold-formed steel is more environmentally friendly: no additional post-treatments are required and the structures are fully recyclable. The lighter weights of the finished buildings also minimise the impact of transport on the environment.

Teamleader Export Europe

Viktoria Kosenko

Guaranteed top quality production

We purchase our steel stock annually in large quantities, ensuring competitive prices and uninterrupted production. Our stock management ensures that sufficient material is always available, avoiding production delays.

Frisomat imports coils that are consistently of high quality. Each coil comes with a quality certificate, allowing us to accurately track its origin and quality. All our processes, from design to production, take place in our facilities in Belgium (Wijnegem) and Brazil, according to the strictest quality standards.

Fast production and assembly

Our prefabricated building system uses galvanised steel formed into columns, beams and other building elements by a process of stamping and profiling (cold forming).

The components of our buildings are perfectly stackable in containers for efficient transport, with the light weight reducing the number of containers and trucks required. Frisomat always has a stock of these prefabricated parts ready, readily available for shipment and assembly.

Upon arrival at the building site, our prefabricated steel structures are immediately ready to be assembled. Thanks to the lightweight steel elements with pre-drilled holes and bolted connections, a small team with a light truck crane can erect the industrial buildings quickly and efficiently, significantly reducing construction time.

Teamleader Export Europe

Viktoria Kosenko

The building process with Frisomat in 10 steps

Discover the 10 steps in the process of an industrial steel building: from your quotation request to the delivery of your building.

Read more